Steel Detailing: A Comprehensive Guide for Precision and Efficiency

In the world of construction and engineering, steel detailing plays a crucial role in transforming architectural designs into reality. It involves the creation of detailed drawings and models that provide precise instructions to fabricators and contractors for the fabrication and erection of steel structures. In this comprehensive guide, we will delve deep into the intricacies of steel detailing, exploring its importance, processes, tools, and best practices to ensure optimal efficiency and accuracy in your construction projects.

1. Understanding the Significance of Steel Detailing

Steel detailing is the bridge that connects the architect’s vision to the actual construction process. It acts as the foundation for fabricators, allowing them to produce steel components with precise measurements and specifications. Proper steel detailing can lead to significant cost savings, as it minimizes material wastage and reduces construction errors.

2. The Steel Detailing Process

2.1. Gathering Project Information

The first step in the steel detailing process is to gather all the necessary project information, including architectural and structural design drawings, specifications, and other relevant documents. Understanding the project’s scope and requirements is essential for accurate detailing.

2.2. Creating Detailed Drawings

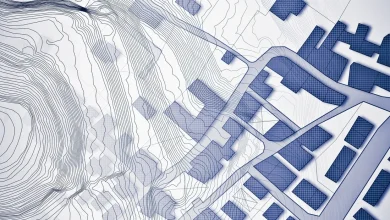

Using specialized software like Tekla Structures, AutoCAD, or Revit, steel detailers create comprehensive drawings that depict every steel component required for the project. These drawings include plans, elevations, sections, and 3D models for a clear visualization of the structure.

2.3. Connection Design

A critical aspect of steel detailing is connection design, ensuring that different steel members are securely connected to handle loads and stresses effectively. This step involves precise calculations to guarantee structural integrity.

2.4. Bill of Materials

The detailer prepares a detailed bill of materials (BOM), listing all the steel components needed for the project. This BOM aids in accurate material ordering and inventory management.

3. Importance of Accuracy and Precision

Accurate steel detailing is of paramount importance to avoid costly mistakes during the construction phase. A minor error in measurements or connections can lead to delays, rework, and budget overruns. Precision in steel detailing ensures that the fabricated components fit together seamlessly on-site, streamlining the construction process.

The Benefits of Optimal Steel Detailing

- Enhanced Structural Integrity: Accurate detailing ensures that the steel components fit together perfectly, minimizing the risk of structural failure.

- Cost Efficiency: Proper detailing helps in reducing material wastage and fabrication errors, leading to cost savings.

- Time Savings: Clear and concise erection drawings speed up the construction process, saving valuable time on the project schedule.

4. Tools and Software for Steel Detailing

4.1. Tekla Structures

Tekla Structures is a powerful 3D modeling software widely used in the construction industry. Its advanced features enable steel detailers to create highly detailed models and drawings efficiently.

4.2. AutoCAD

AutoCAD remains a popular choice for steel detailing due to its versatility and extensive drafting capabilities. It allows detailers to create 2D drawings with ease.

4.3. Revit

Revit is another valuable tool for steel detailing, especially when collaboration with other project stakeholders is essential. It offers Building Information Modeling (BIM) capabilities for a holistic approach to construction.

5. Best Practices for Efficient Steel Detailing

5.1. Collaboration and Communication

Effective communication between architects, engineers, fabricators, and detailers is vital for successful steel detailing. Regular meetings and discussions ensure that everyone is on the same page and can address any potential issues promptly.

5.2. Continuous Learning and Skill Development

Given the ever-evolving nature of construction technology, steel detailers must stay updated with the latest software and industry trends. Continuous learning enhances their efficiency and ensures adherence to best practices.

Conclusion

Steel detailing is the backbone of any successful construction project involving steel structures. By understanding its significance, following best practices, and leveraging advanced software tools, construction professionals can achieve precision, efficiency, and cost-effectiveness. Embracing accurate steel detailing practices is a surefire way to elevate the quality of construction projects and ensure long-term success in the industry.